Hi everyone

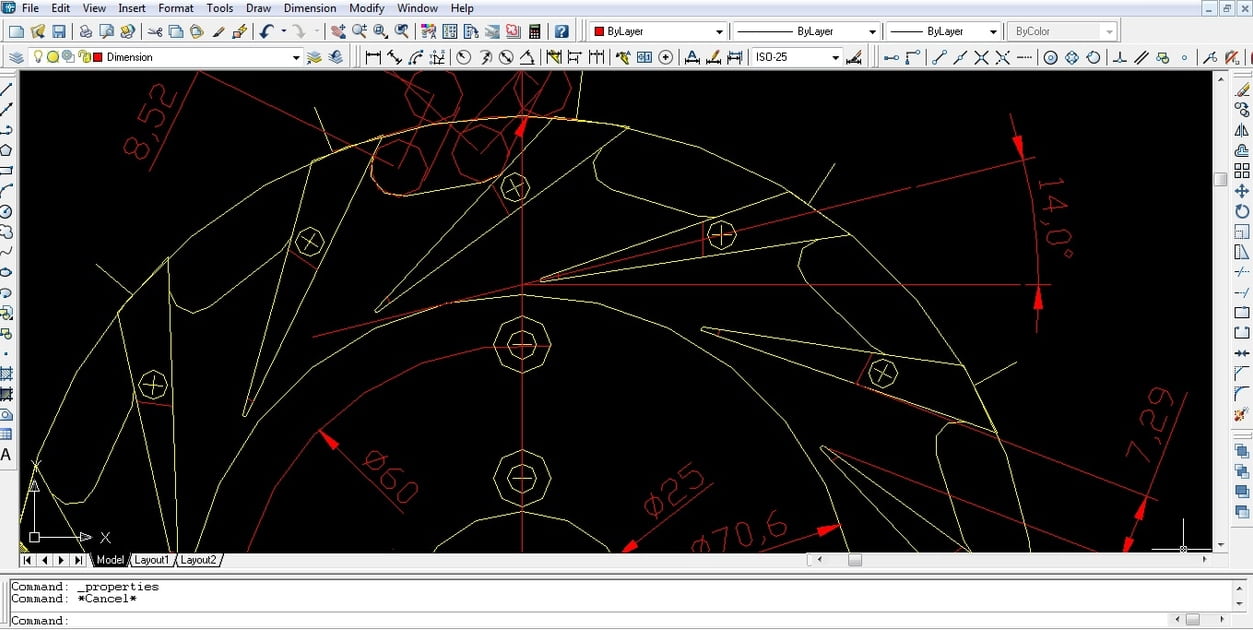

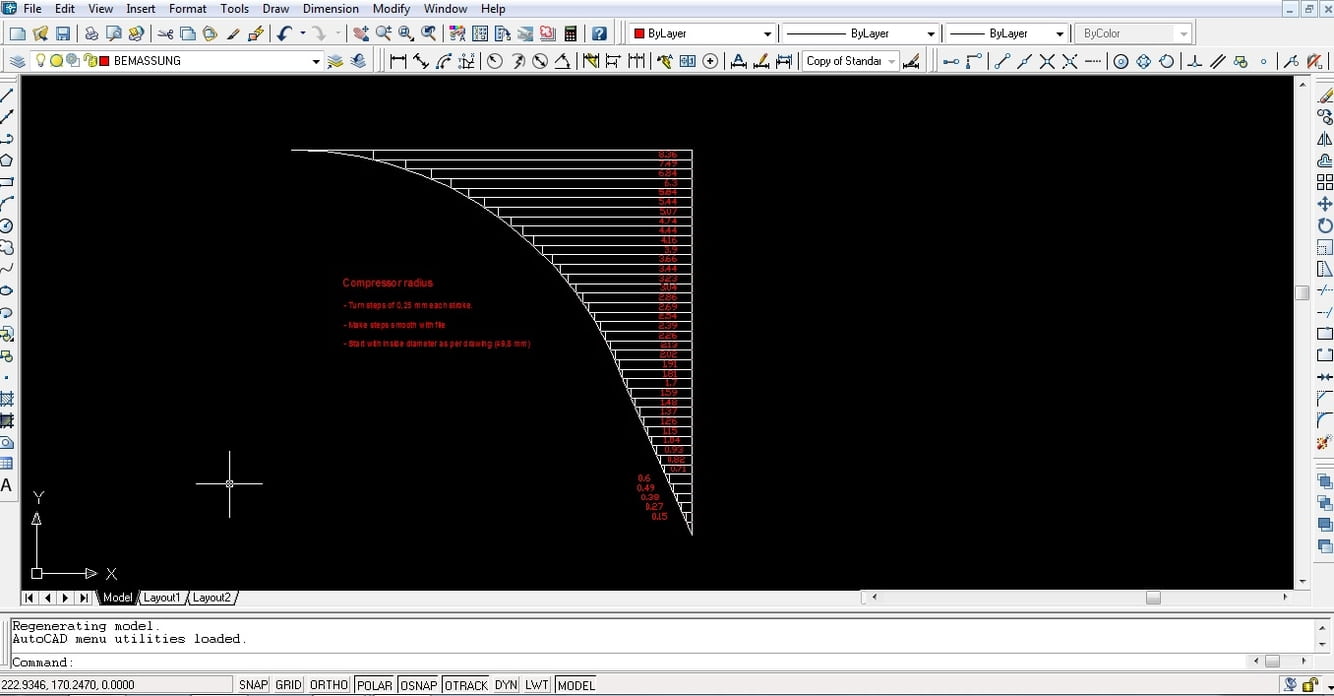

this is my first experience of building a turbine, I have no experience, your beautiful forum is very helpful to me, thank you very much Mr.Gerald RUTTEN for his freely available drawings, I started the construction of the turbine GR 130, the work it will be very long and I will still need your advice, I make a request, Mr. RUTTEN I tried to write to you on Messenger and on your Mail but I never received an answer maybe I have the wrong address, I need some information, would you be available to answer me? thank you

this is my first experience of building a turbine, I have no experience, your beautiful forum is very helpful to me, thank you very much Mr.Gerald RUTTEN for his freely available drawings, I started the construction of the turbine GR 130, the work it will be very long and I will still need your advice, I make a request, Mr. RUTTEN I tried to write to you on Messenger and on your Mail but I never received an answer maybe I have the wrong address, I need some information, would you be available to answer me? thank you